| Product name | MF | Product No | Purity | Specifications | CAS | SP Download | operation | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|||||||||||||||||

English name: Vanadium carbide powder

Molecular formula: VC

The molecular weight:62.95

CAS#:12070-10-9

Melting point:2810℃

Density (20℃) :5.41 g/m3

Appearance:Grey black powder

Solubility: soluble in nitric acid and molten potassium nitrate,insoluble in cold water,hydrochloric acid and sulfuric acid.

Storage:Sealed store in dry,cool environment,should not be exposed to air.

(1)Steel additives

Vanadium carbide can be used as a substitute for Iron Vanadium and is an important Vanadium alloy additive.80%~90% vanadium is used in iron and steel industry.When Vanadium is added to steel in the form of iron vanadium,it reacts with carbon and nitrogen to form fusion-resistant carbonitrides.According to the composition of steel and the temperature of steel treatment process,these compounds can play the role of precipitation hardening and grain refinement in steel.Therefore,Vanadium carbide plays an increasingly important role in the production of Vanadium steel.

(2)Carbide grain growth inhibitor

The results show that adding VC into Cemented carbide makes the cemented carbide have finer grain and higher hardness.As the basic material of modern industry,the development level of Cemented carbide has a very important impact on machine tools, automobiles,engineering machinery and weapons,aerospace, information industry and so on,and is known as the "teeth" of modern industry.

(3)Vanadium carbide in hard alloy as hard phase

In the cemented carbides,we have been trying to use VC to partially replace WC. After efforts,WC-VC-CO alloy has been produced so far.With the same content of Co,WC-VC-CO alloy has higher hardness,wear resistance and corrosion resistance than WC-CO alloy,but the toughness is reduced.

(4)Vanadium carbide as thermal spraying material

A new method of combining Vanadium carbide thin layer on tool surface by metallurgical method has been developed recently abroad,which can prolong tool life.The efficiency of tool machining parts can be increased several times or even tens of times.This method is to place tool steel tool in borate bath containing carbide.Vanadium enters the matrix of tool steel through thermal diffusion and combines with carbon.The hardness of the coating can be up to 3200-3800 HV,and it is not easy to flake,which can greatly improve the tool life.For example,with the VC coated Crl2MoV molding punch processing parts,from the original not coated VC punch 6000 pieces to U26000 pieces;

(5)Vanadium carbide as carbon source for diamond synthesis

In the system composed of VC and Ni70Mn25Co5 alloy with a weight ratio of 1:6, after being treated at a high pressure of 6 GPa and a high temperature of 1500℃ for 20min,VC will decompose and the free carbon can be changed into graphite and diamond.Most of the diamonds produced by this system have erosive surfaces, fuzzy edges and an average particle size of about 20 μm.Therefore, Vanadium carbide can also be used as a new carbon source for diamond synthesis under high pressure and high temperature.

Forsman Dezhou factory independently produces a variety of ultra-high temperature ceramic powders,Vanadium carbide is one of them.At present, the factory can produce nano level,sub-micron level, micron level and other different particle size products.Other granularity customization is acceptable.

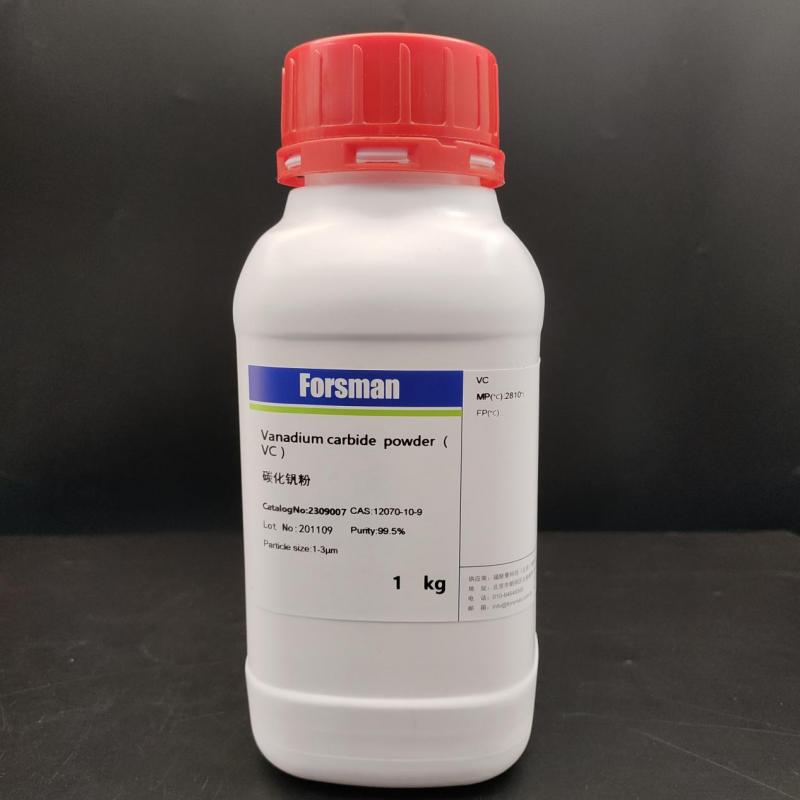

Product display

Fig.| 2309007 Vanadium carbide powder

Fig.| 2309007 Vanadium Carbide 1-3 μm-laser particle size

Fig.| Vanadium Carbide powder product packaging figure