MAX phase

Basic information

MAX phase is a new type of ternary layered compound, which is composed of three elements, M, A and X, and its chemical formula is MN+1AXN (where M: pre-transition metal, A: main group element, X: carbon or nitrogen, N=1, 2, 3...).

As a new family of ceramic materials, MAX phase materials have been developing and expanding continuously, and its member structures are mainly 211, 312 and 413 phases, and 514, 615 and 716 phases have been found. Various elements (Al, Si, Sn, etc.) in A position can form A-site solid solution through a certain proportion of solid solution, which can better adjust the mechanical properties, oxidation resistance and friction properties of MAX materials to a certain extent.

Application of MAX Phase

As the precursor of MXene material, MAX phase material has a wide range of applications. Traditional ceramics are subject to brittleness, Fragile, low impact resistance, Not easy to process and other shortcomings, It is difficult to be widely used, and MAX phase new ceramics just make up for this gap. It combines the properties of ceramics and metals: it not only has good electrical conductivity, high thermal conductivity, machinability, thermal shock resistance, high high temperature plasticity and high high temperature strength of metals, but also has good corrosion resistance, high modulus, low friction coefficient and self-lubrication of ceramic materials. In addition, Ti3AlC2 also has low density, which meets the development requirements of lightweight era. In view of many excellent properties of MAX phase, it can be widely used in the following material fields;

(1) Corrosion resistant materials. Corrosion is one of the culprits of material loss and scrapping, and the material failure caused by corrosion has brought great economic losses to people, and may even endanger people's life safety. MAX phase, as a new corrosion-resistant material, has high surface hardness after carbonization, which can form excellent corrosion-resistant protective layer in theory and has excellent corrosion-resistant ability. Moreover, this surface treatment process is quite inexpensive and easy to operate. In addition, the density of MAX phase materials is much lower than that of the most widely used steel materials. It can also bear a certain impact force, so when partially replacing steel components, it can not only meet the needs of lightweight times, but also meet the traditional needs of anti-corrosion, especially in marine industry and ship transportation with harsh corrosive environment, such as replacing some filters and seals that need anti-corrosion treatment.

(2) High temperature structural materials. At present, the hardness of nickel alloy is only half of that of MAX phase. When the temperature exceeds 1200℃, Ti3AlC2 can still maintain good strength, while Ni-based alloy begins to undergo failure transition, which shows that MAX phase has stronger high temperature stability than Ni-based alloy. In addition, MAX phase has excellent machinability and can meet the requirements of high temperature structural materials. It is an ideal candidate material for preparing high temperature components such as guide blades, turbine blades, high pressure compressor disks, turbine disks and combustion chambers of gas engines.

(3) Low friction coefficient materials and electrical contact materials. MAX phase crystal with large size and high orientation and its self-lubricating property make MAX phase have excellent potential in developing materials with extremely low friction coefficient. Electrical contact materials are required to have good thermal and electrical conductivity, high strength, high temperature stability, excellent self-lubrication and low friction coefficient due to their functional characteristics of current transmission and conversion. MAX phase materials just meet these critical requirements.

(4) Rotating part material. The machinability, dimensional stability, low density and high stiffness of MAX phase are the chips for it to be selected as candidate materials for rotating parts, which has great application potential in the field of disk drive equipment which requires high spatial stability during rotation.

(5) Heat exchange materials. Excellent thermal conductivity is one of the characteristics of MAX phase, and its good thermal conductivity can be maintained at high temperature. Combined with its other characteristics, such as easy machining, stable chemical properties, especially excellent thermal shock resistance, MAX phase materials become one of the candidates for the new generation of heat exchange materials.

Product advantage

The Forsman Texas factory mainly produces ultra-high temperature ceramic powder, and MAX phase ceramic material is one of them. Including M2AX (211), M3AX (312), M4AX3 (413), M2AX2 (212), etc. The MAX phase powders that reach the order of magnitude are Ti3AlC2, Ti3SiC2, Ti2AlC and Nb2AlC. It can produce products with different particle sizes such as nano-scale, sub-micron-scale and micron-scale. The products that have been industrialized are 5μm, 200mesh and 325mesh, which can be provided in tonnage level. The granularity and distribution width of MAX phase can also be controlled by adjusting the production process according to the requirements, and the granularity can be customized by customers. The standard packaging specifications are 2kg and 25kg, and the packaging specifications can be customized according to the customer's feeding quantity.

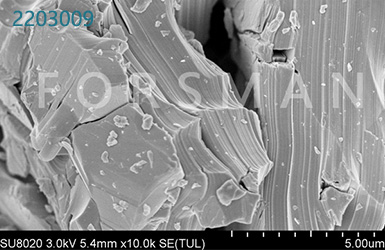

Forsman is one of the early manufacturers of MAX phase materials in China. Because of its high purity, less impurities, stable structure, easy etching and diverse shapes, it is favored by customers at home and abroad. Many research institutes and universities have prepared various high-tech materials by using Forsman's MAX phase products. For example, the School of Materials Science and Engineering of Zhejiang University used Ti3AlC2 as raw material to react with CoS2 after etching to prepare sodium ion batteries with long cycle life. For details of this paper and more Forsman client papers, please refer to Forsman WeChat official accounthttps://mp.weixin.qq.com/s/70cQ85AId3niqTGG5oOywQ

Product display

note:

Our factory gives priority to the supply of “kg or ton” large package products, such as 25kg, 100kg, 500kg and 1 ton, 10 ton products. If you need a smaller package of products, you can also call or leave a message to us, we provide you with customized services.The packaging can be customized according to the customer's feeding quantity.

Fig. | 4102008 Nb4AlC3 - 200 mesh